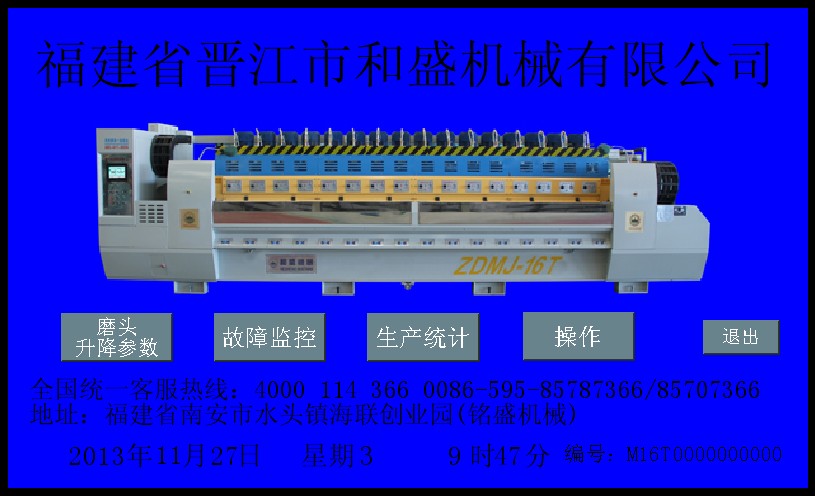

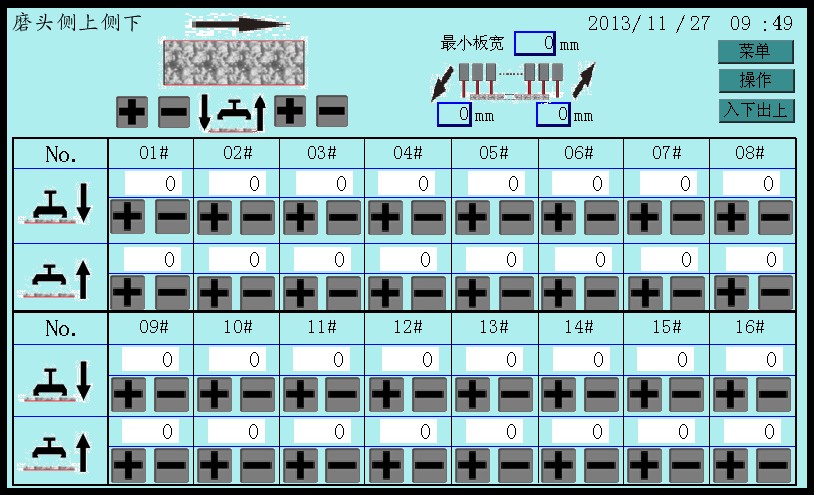

1:The polishing head with new structure could adjust rubber elasticity of each polishing head according to the different grinding materials, so the fineness and flatness of tileplate produced under the same conditions will be increased over 10%. The design of the polishing head could also avoid damaging the polished materials to maximum limit.

2:The linear guide (imported from Taiwan) is adopted as for side beam traveling, so the crossbeam is stable without vibration and jacking-up during traveling.

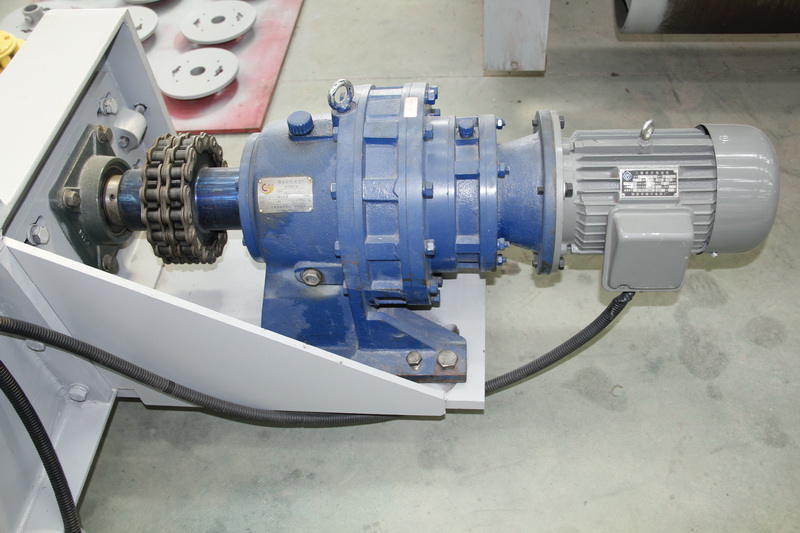

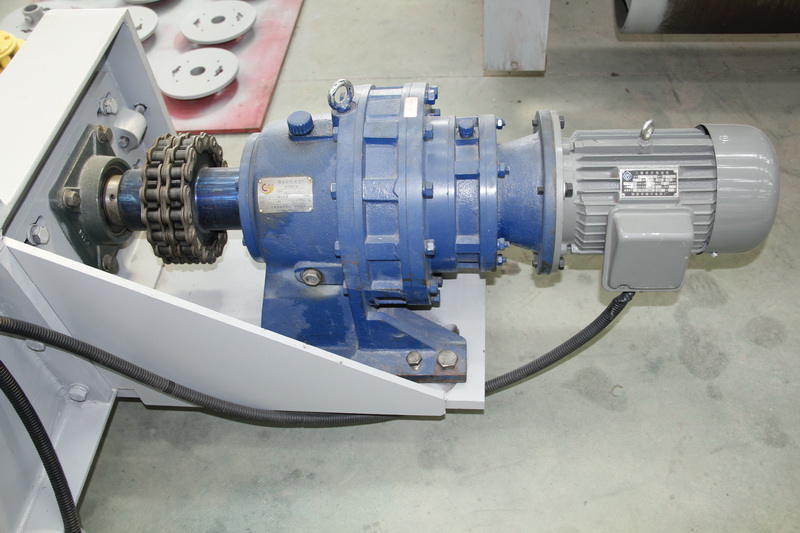

3:The rear of 20 (24) heads adopts cascade mechanism of double gear reducer promising powerful driving and long service life.

4:The rear of 12 (16) heads adopts a mechanism of single gear reducer.

5:Gear reducer is connected with idler wheel by chain so as to reduce possibility of shaft broken

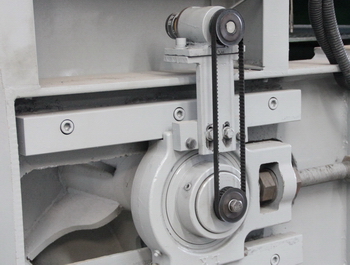

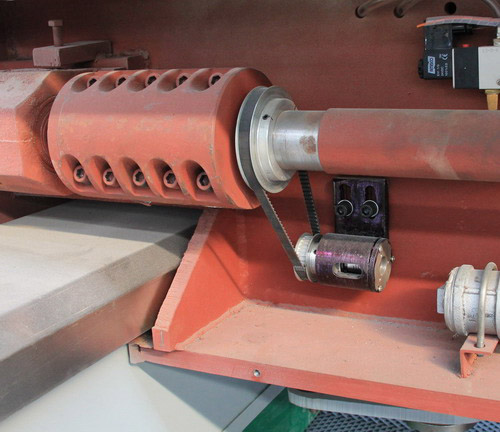

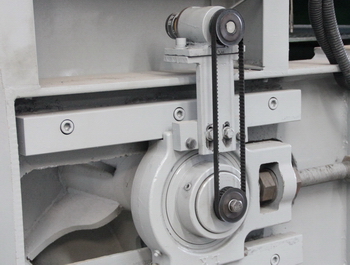

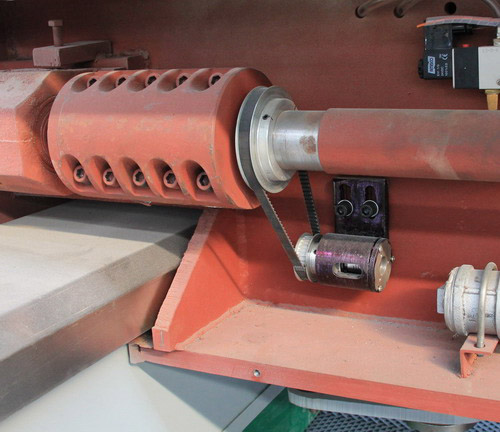

6:The rotary encoder for side beam traveling adopts synchronous belt drive with features of stable signal and convenient maintenance, etc.

7:Primer adopts epoxy aluminum primer for good antirust performance and long service life.

8:Pneumatic components (including cylinder, air valve and regulating switch) adopt Taiwan "AirTAC" products with stable quality and lower fault rate.

9:Main motor is made according the old standard for powerful drive. Aluminum casing could lower total weight of crossbeam, and be featured as light and quick during swing which is helpful to increase yield.

10:Gear reducer is connected with idler wheel by chain so as to reduce possibility of shaft broken.

11:Inductor for tileplate feeding could regulate according the different thickness of tileplate.

|